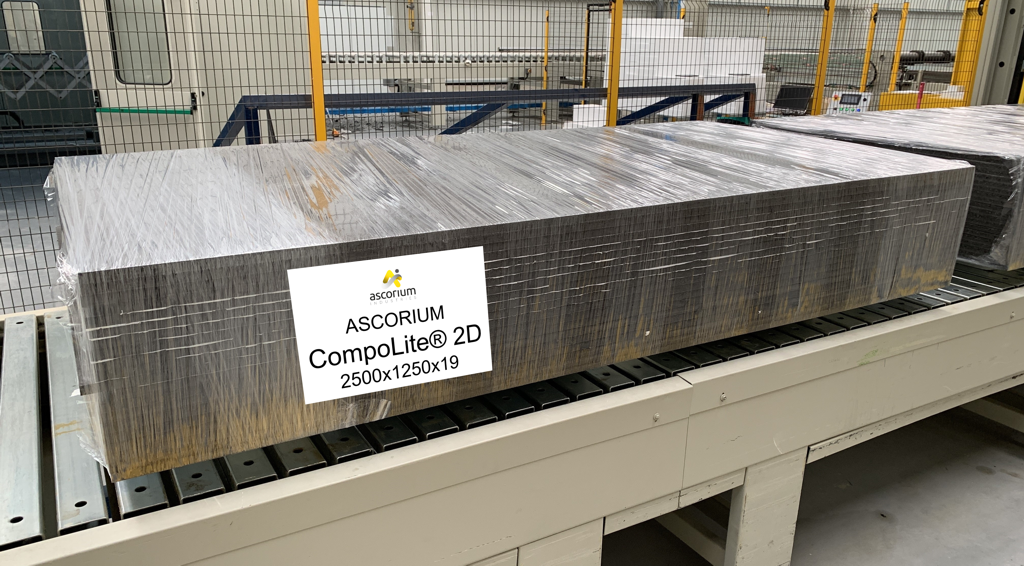

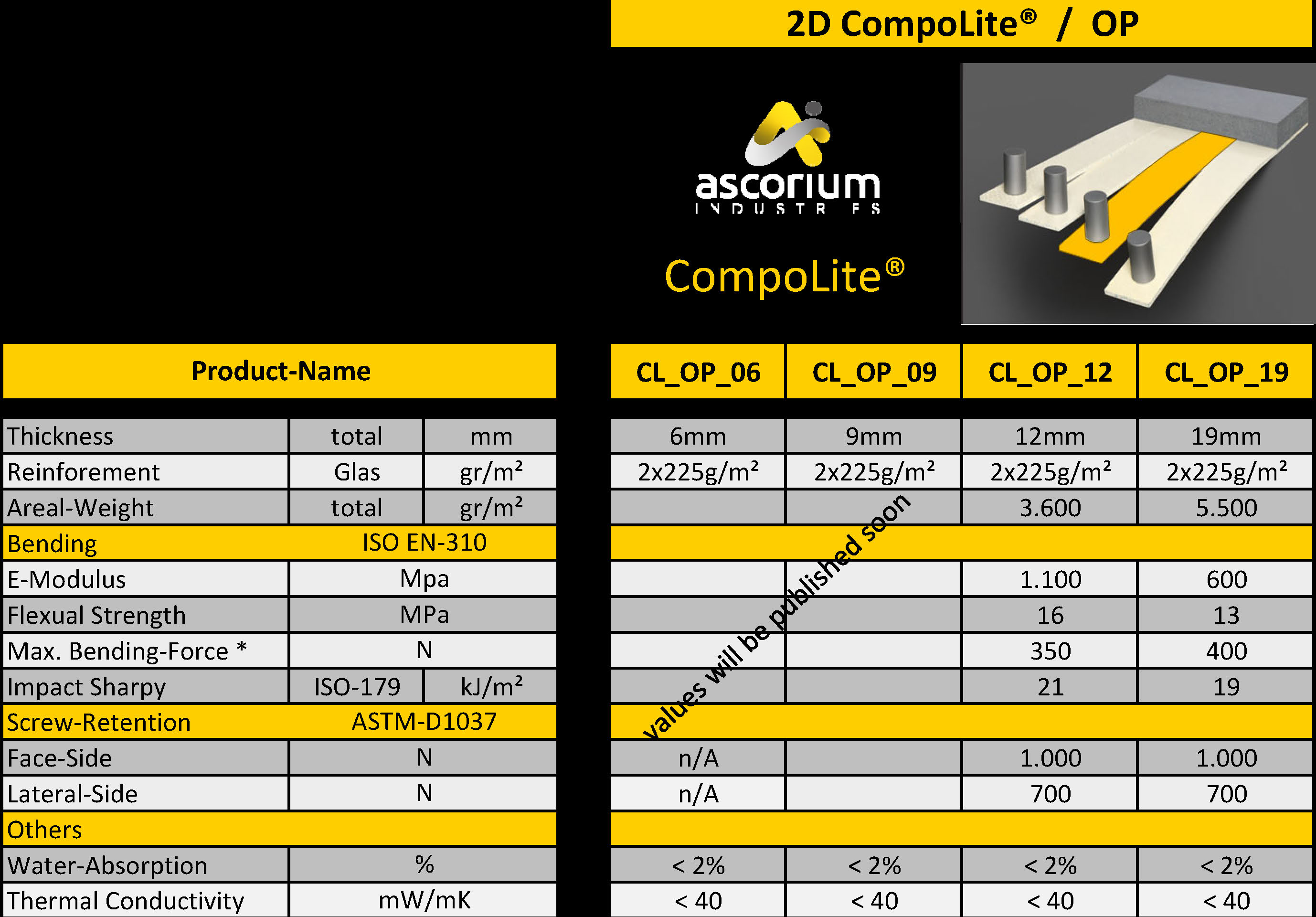

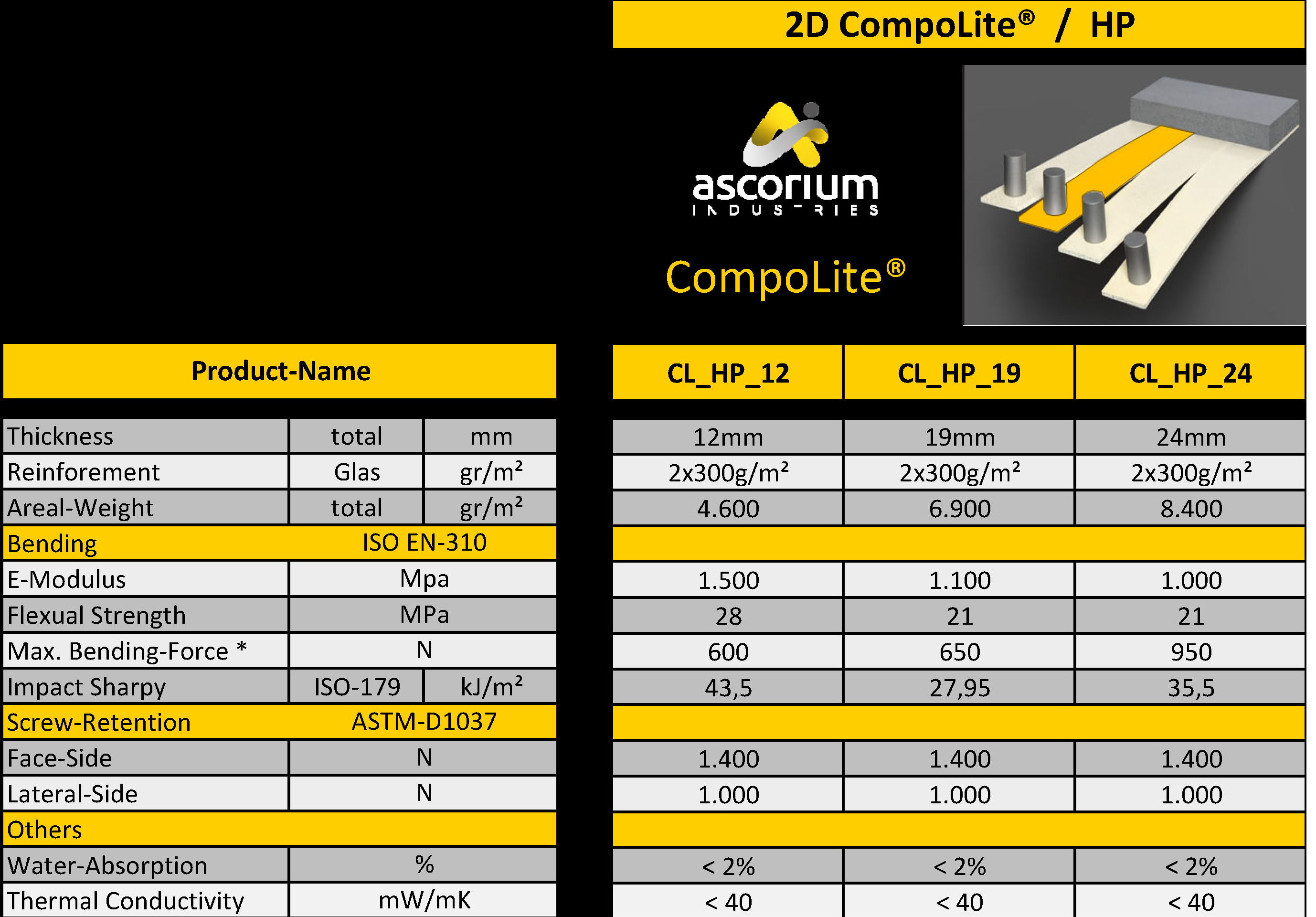

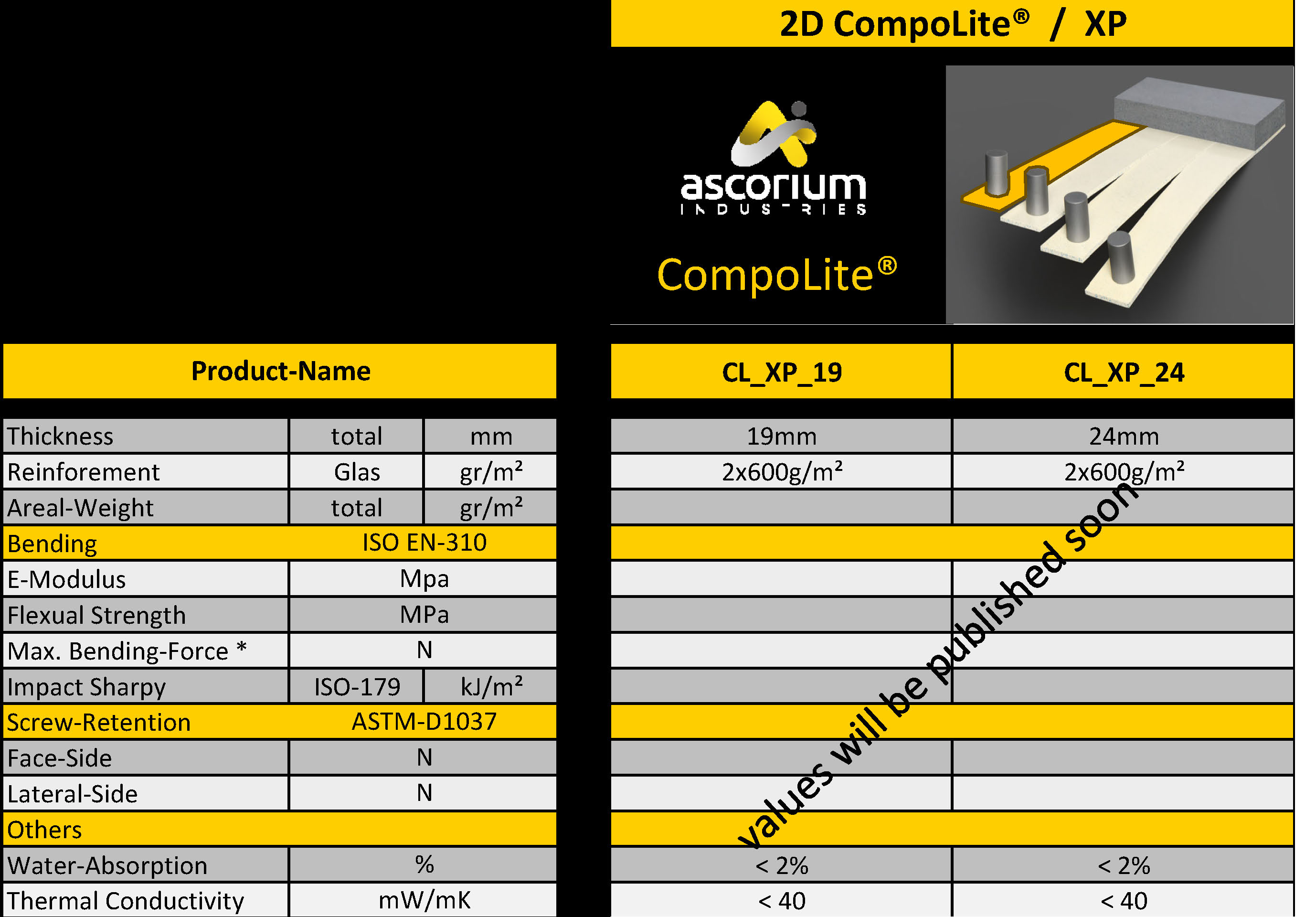

CompoLite® 2D

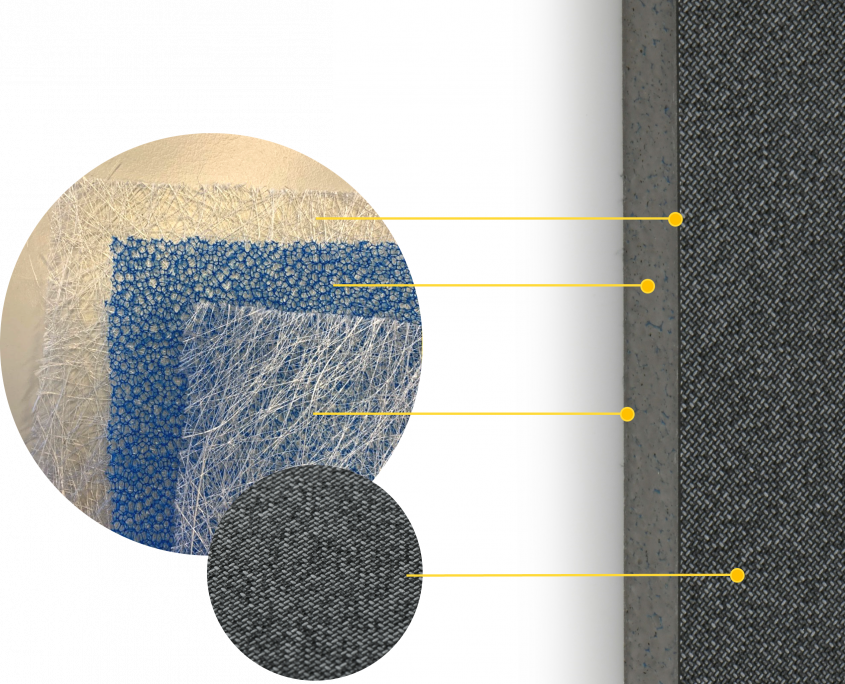

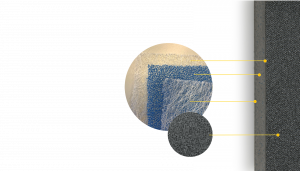

The reinforcement fiber mat is 100 % embedded with polyurethane, but still located at the outer surface of the sandwich to realise optimal material characteristics in stiffness and strength.

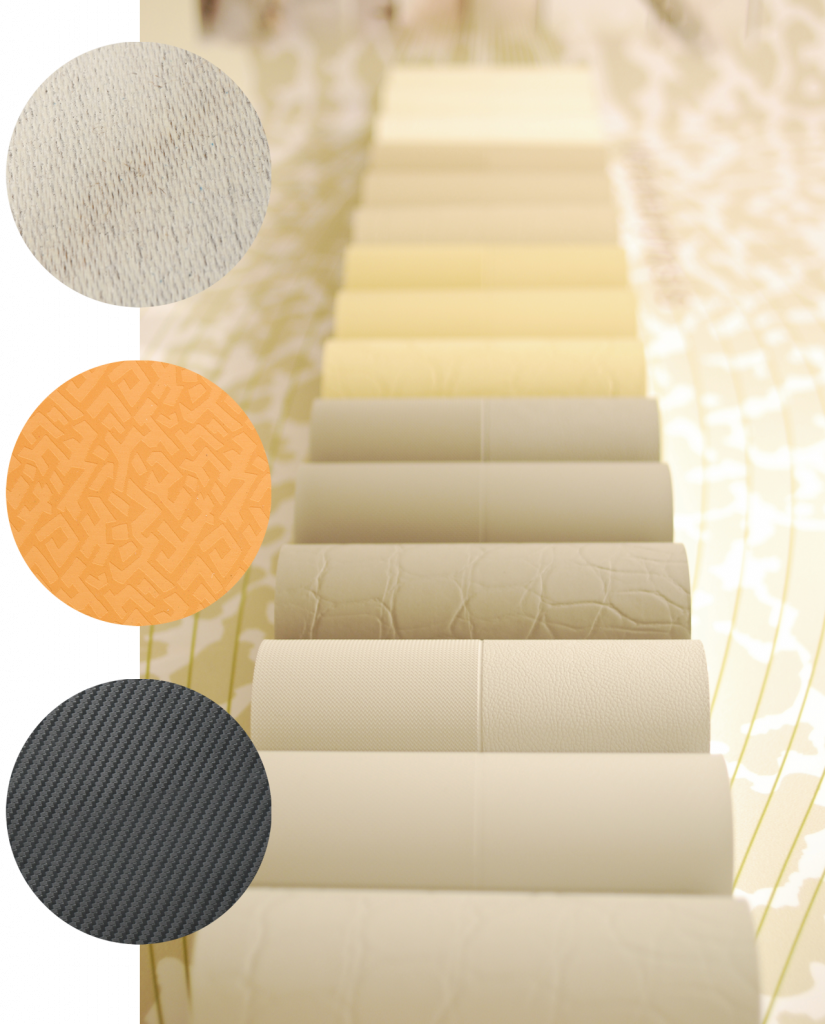

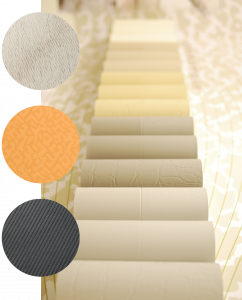

CompoLite® substrates may be finished with all surfaces commonly used in the marine and automotive interior trim sector. Any decorative material is suitable, which improves the already excellent thermal and acoustic insulation properties.

Applications

For structural and semi-structural applications in a variety of industries including

Transportation walls, flooring, structural elements

Marine structural grid, interior applications, flooring

Construction elements storage & packaging covers, walls, case elements

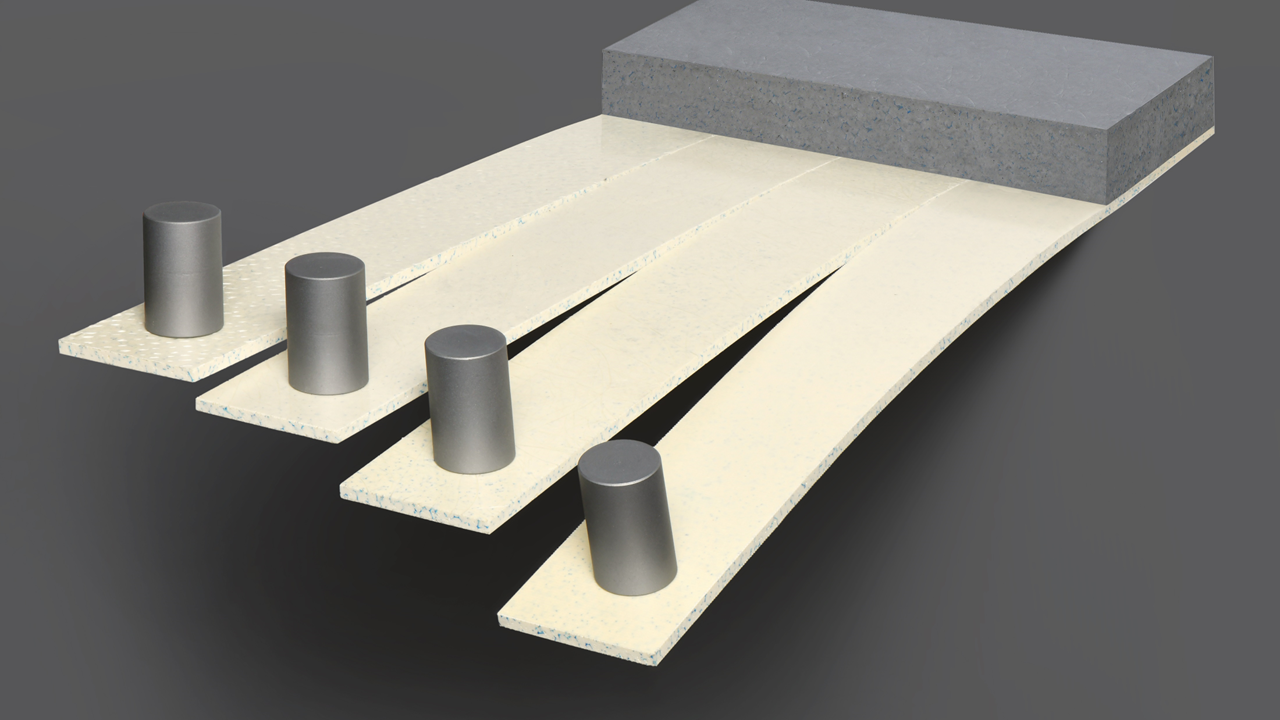

Deliverable in a variety of thicknesses, colors, haptics and material performance levels.

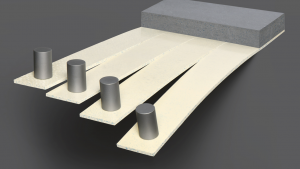

Possibility of multi-layer setup e.g., aramid or Kevlar inclusion.